Home / Handling / Transport conveyor / Transport conveyor TCH

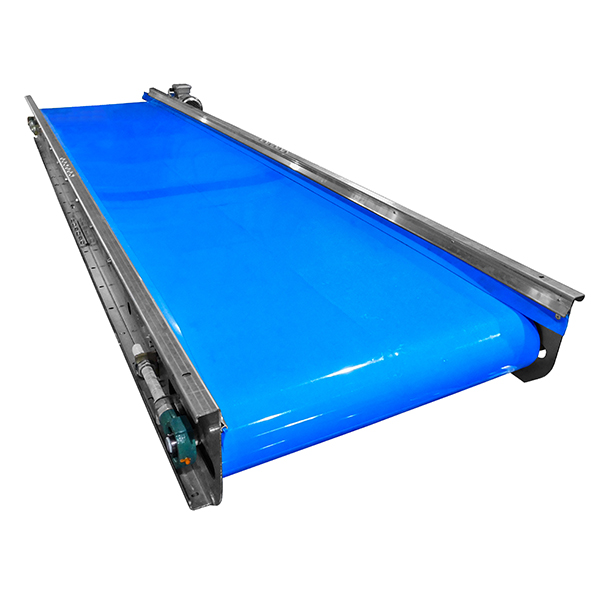

Transport conveyor TCH

The transport conveyor is designed for conveying. This type of transport belt has high side panels. On demand, the belt can be made of PVC, PU, or rubber.

The transport conveyor is designed for conveying. This type of transport belt has high side panels. On demand, the belt can be made of PVC, PU, or rubber. Belts can be supplied with straight and round welded cleats. The shape of the cleats is 15×15.

On demand, a cover is mounted on the top and bottom of the machine. This cover can be made from galvanized steel or stainless steel. On demand, a frequency inverter is included to control the speed.

Characteristics

- Available in 20, 40, 60, 80, 100 and 120 cm width

- Belt available in 100 – 2500 in steps of 25 cm

- On demand, cleats can be straight or round welded

- On demand, the topside cover and bottom side cover can be made from galvanized steel or stainless steel

- On demand, a frequency inverter is included to control the speed

- Available in various options like zinc plated steel, stainless steel, and painted mild steel

Specifications

| TCH 20 | TCH 40 | TCH 60 | TCH 80 | TCH 100 | TCH 120 | |

|---|---|---|---|---|---|---|

| Width of the machine (cm) | 20 | 40 | 60 | 80 | 100 | 120 |

| Length of the machine (cm) | 100 t/m 2500, steps of 25 cm | 100 t/m 2500, steps of 25 cm | 100 t/m 2500, steps of 25 cm | 100 t/m 2500, steps of 25 cm | 100 t/m 2500, steps of 25 cm | 100 t/m 2500, steps of 25 cm |

Options

- Material and treatment (frame)

Zinc plated steel

Frame is made from zinc plated steel. The bearings and drive/idle rollers are from mild steel

Stainless steel

Frame is made from stainless steel. The bearings and drive/idle rollers are from mild steel

Painted mild steel

Frame is made from painted mild steel. The bearings and drive/idle rollers are from mild steel

- Belt

PVC

The belt is made of PVC

PU

The belt is made of PU

Rubber

The belt is made of rubber

- Cleats

Straight

The type of cleats is straight

Round welded

The type of cleats is round welded

- Cleats shape

15 x 15

The shape of the cleats is 15 x 15

- Electrical control

No electric

Motors only. Wiring, additional sensors and/or control panel are not included

Stand-alone

Motors, necessary sensors, switch box and control box

Central control in line

Motors and necessary sensors

- Frequency inverter

Speed adjustment

A frequency inverter is included to control the speed

- Material and treatment (electrical panel)

Painted mild steel

The electrical panel is made from painted mild steel

Stainless steel

The electrical panel is made from stainless steel

- Material and treatment (bottomside cover)

Zinc plated steel

A cover is mounted on the bottom of the machine, made from zinc plated steel

Stainless steel

A cover is mounted on the bottom of the machine, made from stainless steel

Length of bottomside cover

0 t/m 2500, steps of 25 cm

- Material and treatment (topside cover)

Zinc plated steel

A cover is mounted on top of the machine, made from zinc plated steel

Stainless steel

A cover is mounted on top of the machine, made from stainless steel

Length of topside cover

0 t/m 2500, steps of 25 cm

- Switch

Maintenance

A maintenance switch is included

Reverse

A reverse switch is included

Start/stop

A start/stop switch is included

- Product sensor

Sensor

A product sensor is included

- Bracket

Bracket

There is a bracket included

- Extra motor

0.37 kW

An extra 0.37 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

0.75 kW

An extra 0.75 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

1.1 kW

An extra 1.1 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

1.5 kW

An extra 1.5 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

2.2 kW

An extra 2.2 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

3 kW

An extra 3 kW motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

0.37 kW middle

An extra 0.37 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

0.75 kW middle

An extra 0.75 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

1.1 kW middle

An extra 1.1 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

1.5 kW middle

An extra 1.5 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

2.2 kW middle

An extra 2.2 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors

3 kW middle

An extra 3 kW middle motor is included to make sure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors