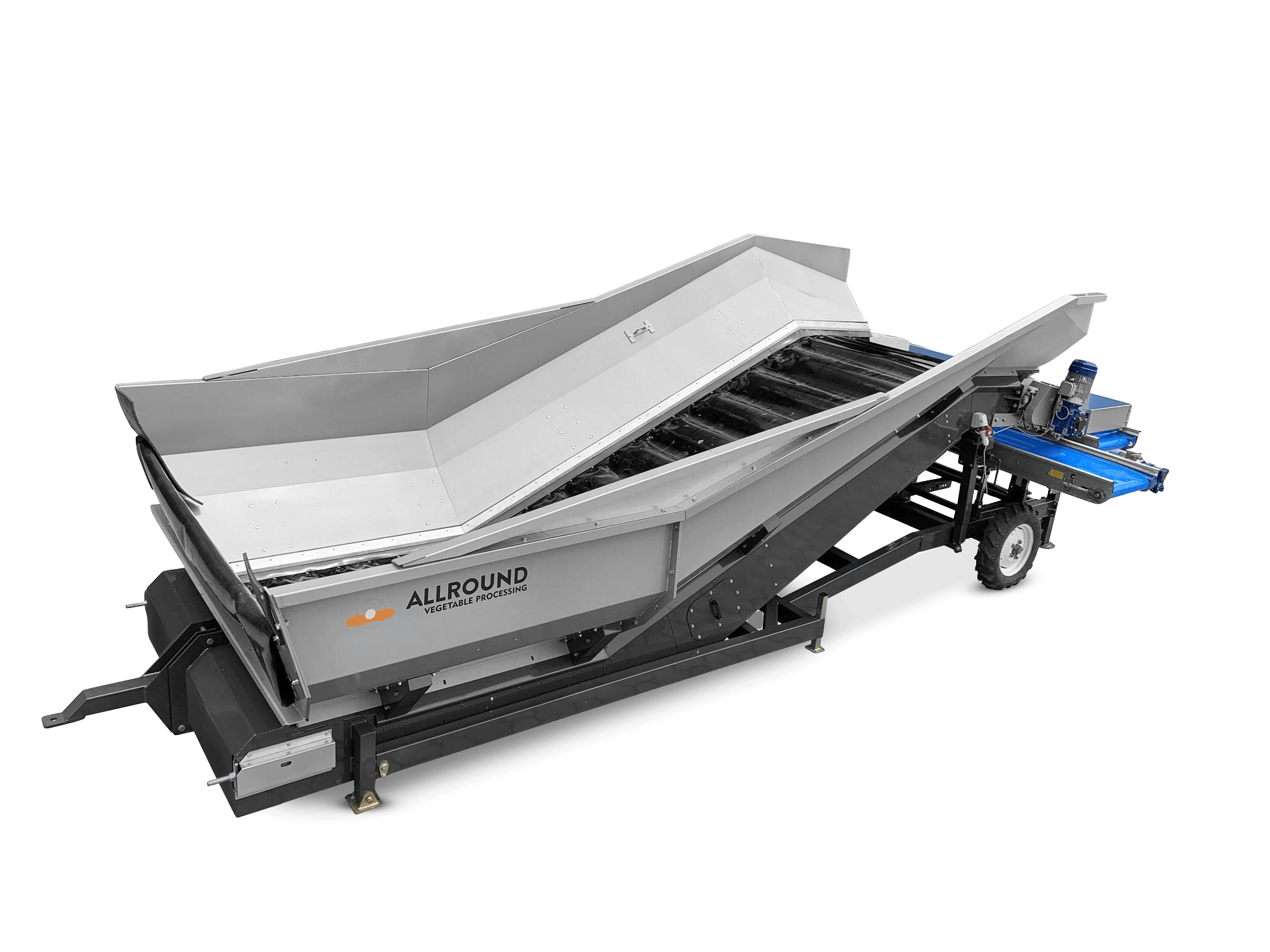

The receiving hopper is designed to act as a buffer. It can either be used to feed processing lines or loading and unloading lines in storage solutions.

The receiving hopper is designed in such a way that it can be fed with produce via different types of trailers, boxes, or big bags. After the machine is filled, a moving floor conveys the produce diagonally up towards the outfeed. The angle of the floor ensures an even product flow. Additionally, a frequency inverter is installed on the machine to allow for adjustable product flow. The machine is equipped with wheels, making it easy to relocate over short distances.

On demand, a sensor can be installed to detect and control the produce output. This sensor sends a signal to start or stop the moving floor, thereby controlling the output of the receiving hopper.

Characteristics

- Models are available in different widths and lengths

- Used to feed processing lines or cold storage rooms

- Can be fed via different types of trailers, boxes, or big bags

- Heavy-duty belts are robust and long-lasting

- Variable speed conveyor with dosing sensor

- Simple access allows for easy cleaning and maintenance

- Wheels make it easy to relocate over short distances

- A frequency inverter can adjust the floor speed to manage the product flow

- On demand, a sensor can be provided to detect and control the output of produce

Specifications

| Width of the machine (cm) | Length of the incline part (cm) | Length of the straight part (cm) | Total content (m3) | Effective content (m3) | |

|---|---|---|---|---|---|

| ARH 160 | 160 | 400 | 0 | 9.0 | 5.4 |

| 160 | 400 | 100 | 9.7 | 5.8 | |

| 160 | 400 | 200 | 12.2 | 7.3 | |

| 160 | 400 | 300 | 14.8 | 8.8 | |

| ARH 200 | 200 | 400 | 0 | ||

| 200 | 500 | 0 | |||

| 200 | 600 | 0 | |||

| ARH 240 | 240 | 600 | 0 | ||

| 240 | 700 | 0 | |||

| 240 | 800 | 0 | |||

| 240 | 900 | 0 | |||

| ARH 300 | 300 | 700 | 0 | ||

| 300 | 800 | 0 | |||

| 300 | 900 | 0 |

Options

- Material and treatment (frame)

- Material and treatment (plating)

- Electrical control

- Material and treatment (electrical panel)

- Dosing Sensor

- Dosing mill

- Subframe – wheels

- Subframe – first part

- Subframe – second part

- Subframe – third part

- Subframe – fourth part

- Waste belt

- Chain greasing