Home / Inspection / Inspection unit with roller / Inspection unit RIZ

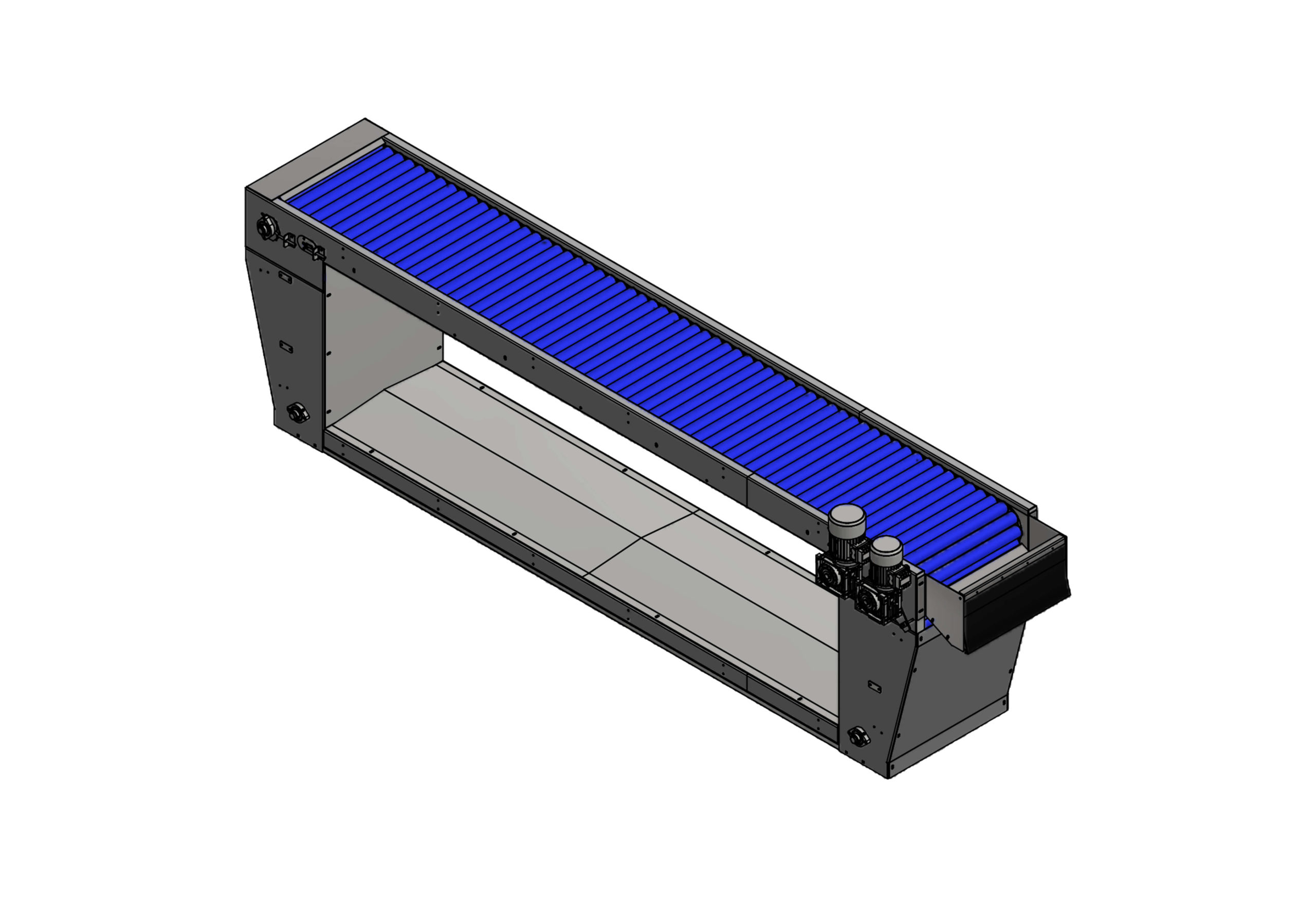

Inspection unit RIZ

The inspection unit RIZ is used for manual sorting of the waste between the produce.

The inspection unit RIZ is used for manual sorting of waste between produce. The produce is transported and rotated over rollers for inspection. Waste and rejected produce can be picked out. The rotating speed can be adjusted. Dust falling through the rollers is collected in a bin. This type is meant for standing and sitting. An outfeed chute to separate the waste of the aisle is included. The inspection can be made with the cabin, as per the customer’s requirement, which can be used to protect against noise and dust from (the machines) outside the cabin.

Characteristics

On demand, the rollers in the inspection table can be made from stainless steel AISI304 or PVC

On demand, the electrical panel can be made from stainless steel AISI304 or a painted mild steel

A waste chute is included on the side. The chute will guide waste to a transport conveyor or box

In the middle of the conveyor, an aisle is included. There is a separate passage in the outfeed chute

A light strip is added to the inspection unit to make the product more visible

A safety cord is included. By pulling this safety cord, the machine or line will stop

A frequency inverter is included to control the speed

Specifications

| RIZ 60 | RIZ 80 | RIZ 100 | RIZ 120 | RIZ 140 | |

|---|---|---|---|---|---|

| Width of the roller (in cm) | 60 | 80 | 100 | 120 | 140 |

| Length of the machine (in cm) | 125 to 650, steps of 25 cm | 125 to 650, steps of 25 cm | 125 to 650, steps of 25 cm | 125 to 650, steps of 25 cm | 125 to 650, steps of 25 cm |

OptionsItems marked with * are optional

- Material and treatment (frame)

- Rollers

The roller diameter is Ø 30 mm

The pitch of the chain is 3,8 cm

The gap size is 8 mm

The roller diameter is Ø 32 mm

The pitch of the chain is 3,8 cm

The gap size is 6 mm

The roller diameter is Ø 56 mm

The pitch of the chain is 6,3 cm

The gap size is 7 mm

- Electrical control

- Frequency inverter

- Material and treatment (electrical panel)

- Waste collection – chute*

- Waste collection – aisle*

- Light strip*

- Safety cord*

- Roller speed*