Home / Cleaning / Roller set / Fixed roller set

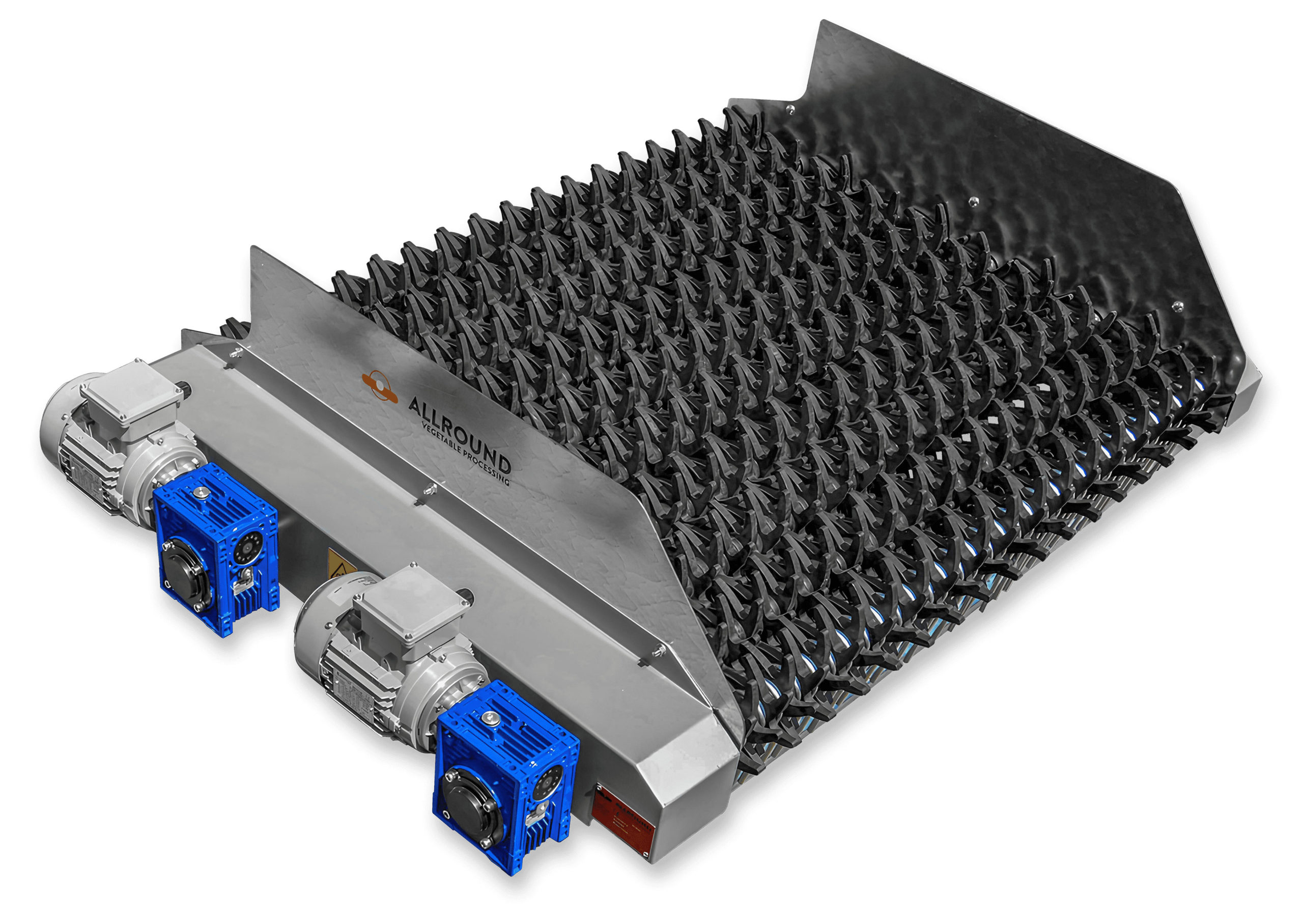

Fixed roller set

The fixed roller set are for pre-cleaning. On demand, the roller set can be supplied in spiral, steel spiral, diabolic, and soft rollers.

Fixed roller sets are for pre-cleaning. The produce moves over the rollers, while dirt and skins fall between the rollers. On demand, the roller set can be supplied in spiral, steel spiral, diabolic, and soft rollers. Each roller set has unique qualities and applications. An on demand frequency inverter can be included to control the speed.

Depending upon product and soil conditions, the type of roller set is decided on demand. On demand fixed rollers can be supplied as a stand alone unit or mounted on a reception hopper.

On demand, the fixed finger roller set can be provided star with 12 fingers and 6 fingers. 12 fingers is used for small products whereas 6 fingers is used for bigger products. The unique feature of the finger roller set is that it transports the crop through rubber fingers.

Characteristics

- Models are available in 6 and 8 rollers.

An on demand frequency inverter is included.

- On demand machines can be supplied as stand-alone units or mounted on hoppers.

- Fixed roller sets are mainly used for pre-cleaning.

- Wide range of applications.

On demand, the fixed finger roller set can be provided to the star with 12 fingers and 6 fingers

On demand rollers like spiral, steel spiral, diabolic, and soft can be supplied

Specifications

| RE 80 | RE 100 | RE 120 | RE 160 | RE 240 | |

|---|---|---|---|---|---|

| Width of the machine (in cm) | 80 | 100 | 120 | 160 | 240 |

| Amount of rollers | 6, 8 | 6, 8 | 6, 8 | 6, 8 | 6, 8 |

Options

- Material and treatment (cover)

- Rollers

Distance between: rollers 16 mm

Diameter: roller Ø 89 mm

Including scrapers

Thorough removing of dirt and suitable for small stones

Distances between: spirals 7 mm, rollers 31 mm

Diameters: spiral Ø 98 mm, roller Ø 74 mm

Pitch spirals: 25 mm

Distances between: diabolics 15 mm, rollers 44 mm

Diameters: inner Ø 61 mm, outer Ø 90 mm

Rollers equipped with stars, each containing 12 fingers, shore 40°

Rollers equipped with stars, each containing 6 fingers, shore 65°

Less damage of product

Distance between rollers 25 mm

Diameter: Ø 80 mm, shore 45°

- Electrical control

- Frequency inverter

- Material and treatment (electrical panel)

- Material and treatment (subframe)

- Height of subframe

- Product collection – chute