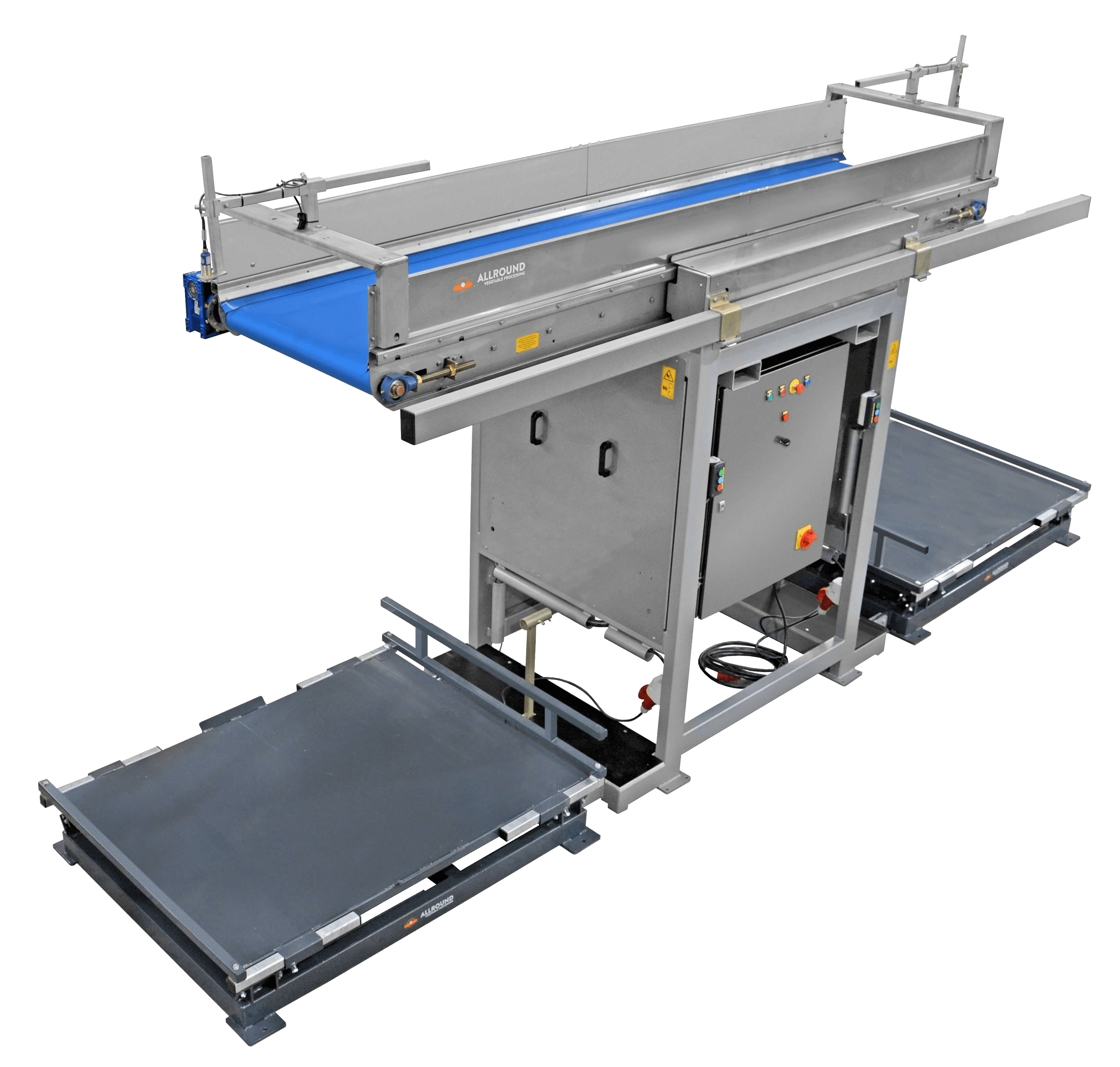

The filling station is used for filling. After a box is placed the horizontal conveyor starts filling. When the sensor detects produce, the belt moves above the box so it can be filled flatten/even. Because the filling station can hold 2 boxes, the machine is capable of filling without interruptions.

On demand, Safety fences with a sensor are included. The sensor detects if someone walks between the fences, which will stop the machine from functioning. On demand, the frame is made from painted mild steel and zinc plating. The bearings and drive/idle rollers are made of mild steel.

Characteristics

- Models are available in 60 and 80 cm width

- The length of the machine available is 350 – 750 in steps of 25 cm

- Integrated box detect sensor for seamless operation

- Produce level sensor signals for when to adjust the placement of the conveyor

- The frame is made from painted mild steel and zinc plating

- On demand, Safety fences with a sensor are included

- Forklift tubes so the box filler can be easily moved

- The tower light alerts the forklift operator when a box is full

Specifications

| FS 80 | |

|---|---|

| Width of the machine (cm) | 80 |

| Length of the machine (cm) | 350, 750 |

Options

- Material and treatment (frame)

Painted mild steel

Frame is made from painted mild steel. The bearings and drive/idle rollers are from mild steel

Stainless steel

Frame is made from stainless steel AISI304. The bearings and drive/idle rollers are from mild steel

- Electrical control

No electric

Motors and necessary sensors

Stand-alone

Motors, necessary sensors and control panel with HMI. The length of the cable is 5, 10, 15 or 20 meter

- Material and treatment (electrical panel)

Painted mild steel

The electrical panel is made from painted mild steel

Stainless steel

The electrical panel is made from stainless steel AISI304