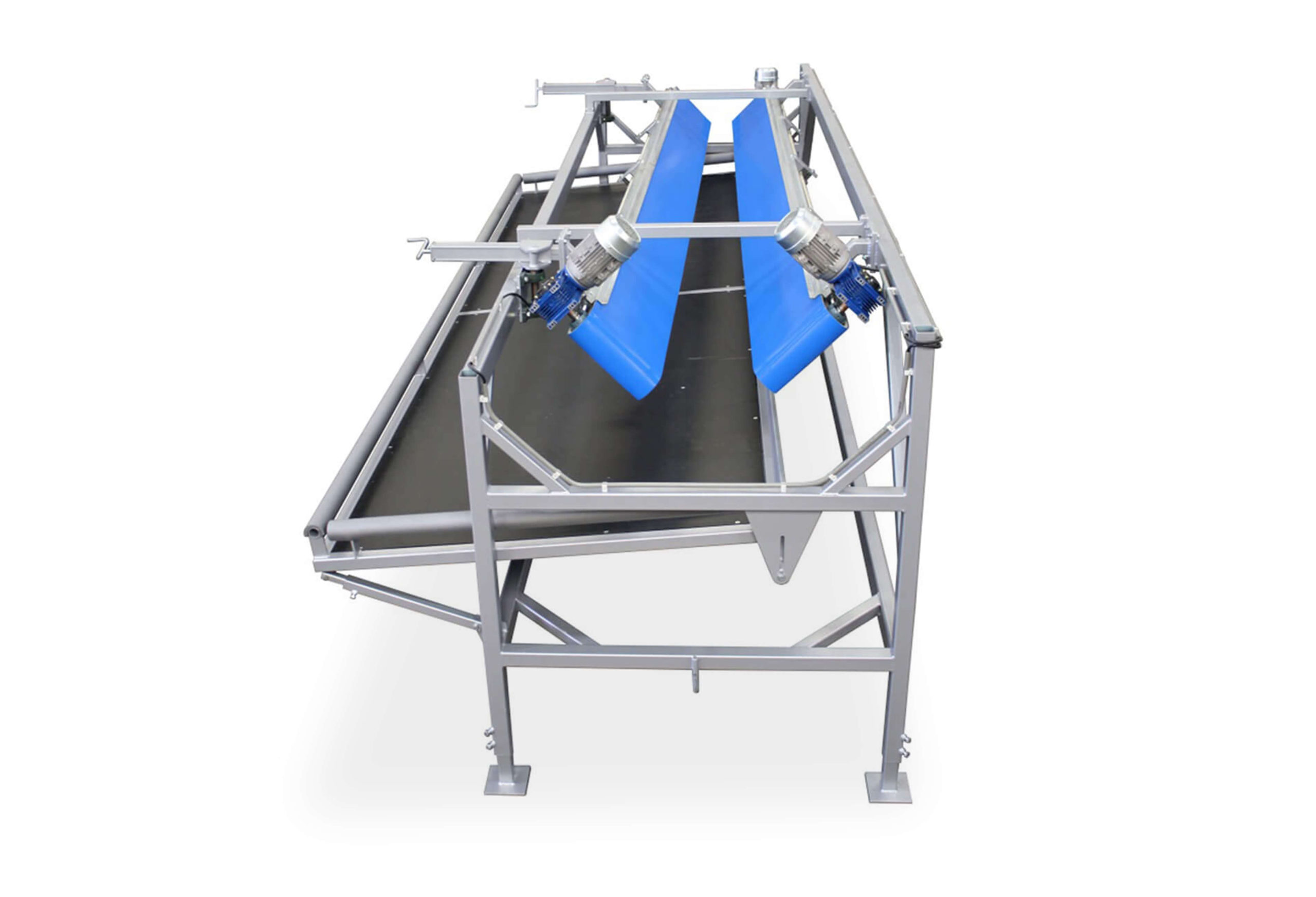

The cabbage grader is designed for grading. Two belts are mounted opposite to each other at an angle; the cabbage is transported between these belts. Between the belts, there is a gap (grading size) with different distances from the beginning to the end. When the cabbage reaches the right grading size, it falls between the belts.

Characteristics

The belts are made of PVC, with a width of 30 cm and an angle of 45°

- The grading size can be manually adjusted by spindles, ranging from 0 mm to 360 mm

- The frame can be made from painted mild steel, zinc plating, and stainless steel AISI304

- The bearings and drive/idle rollers are always made from mild steel

A frequency inverter is included to control the speed

Specifications

| CG 450 | |

|---|---|

| Length of the machine (in cm) | 450 |

Options

- Material and treatment (frame)

Painted mild steel

Frame is made from painted mild steel and zinc plating. The bearings and drive/idle rollers are from mild steel

Stainless steel

Frame is made from stainless steel AISI304. The bearings and drive/idle rollers are from mild steel

- Belt

PVC

The belts are made of PVC

The width of the belts is 30 cm

The angle of the belts is 45°

The width of the belts is 30 cm

The angle of the belts is 45°

- Electrical control

No electric

Motors and necessary sensors

Stand-alone

Motors, necessary sensors and control panel. The length of the cable is 5, 10, 15 or 20 meter

Central control in line

Motors and necessary sensors

- Frequency inverter

Frequency inverter

A frequency inverter is included to control the speed

- Material and treatment (electrical panel)

Painted mild steel

The electrical panel is made from painted mild steel

Stainless steel

The electrical panel is made from stainless steel AISI304

- Adjustment grading size

Manual

The grading size can be adjusted manually by spindles. The grading size is adjustable between 0 mm and 360 mm