Home / Handling / Transport conveyor / Transport conveyor VB

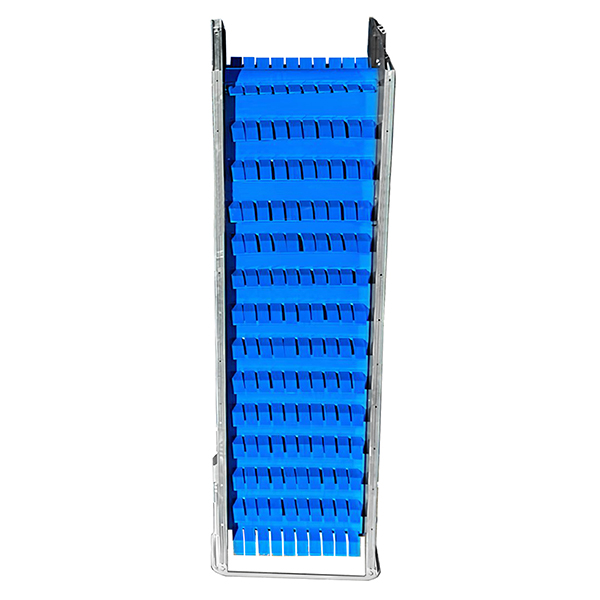

Transport conveyor VB

The transport conveyor is designed for conveying. This type is the transport belt to convey products vertically. On demand, the belt can be made of PVC or PU.

This transport conveyor is designed for conveying. This type is the transport conveyor to convey products vertically. On demand, the belt can be made of PVC or PU. It is available in opening sizes of 11 and 16 cm to suit various diameter products.

An extra motor can be included on demand to ensure the belt can move both ways. If this option is selected, the originally selected power (kW) must be divided between the two motors. An on demand, frequency inverter can be added to control the speed of the belt.

The Frame can be made on demand from zinc plated steel, stainless steel, and painted mild steel.

Characteristics

- Used to convey product vertically

- The belt can be made of PVC or PU

- A frequency inverter can be added on demand

- An extra motor can be included on demand

- Various length and width options are available to suit your design requirements

- Belts can be supplied with various cleat options like fingers, THW and THW interrupted

- Available in opening sizes of 11 and 16 cm to suit various diameter products.

Specifications

| VB 40 | VB 60 | VB 80 | |

|---|---|---|---|

| Width of the machine (cm) | 40 | 60 | 80 |

| Length of the machine (cm) | 150 t/m 600, steps of 25 cm | ||

| Opening size of the vertical belt (cm) | 11, 16 | ||

OptionsItems marked with * are optional

- Material and treatment (frame)

- Belt

- Cleats*

- Electrical control

- Frequency inverter*

- Material and treatment (electrical panel)

- Support*

- Switch*

- Product sensor*

- Bracket*

- Motor on top*

- Extra motor*