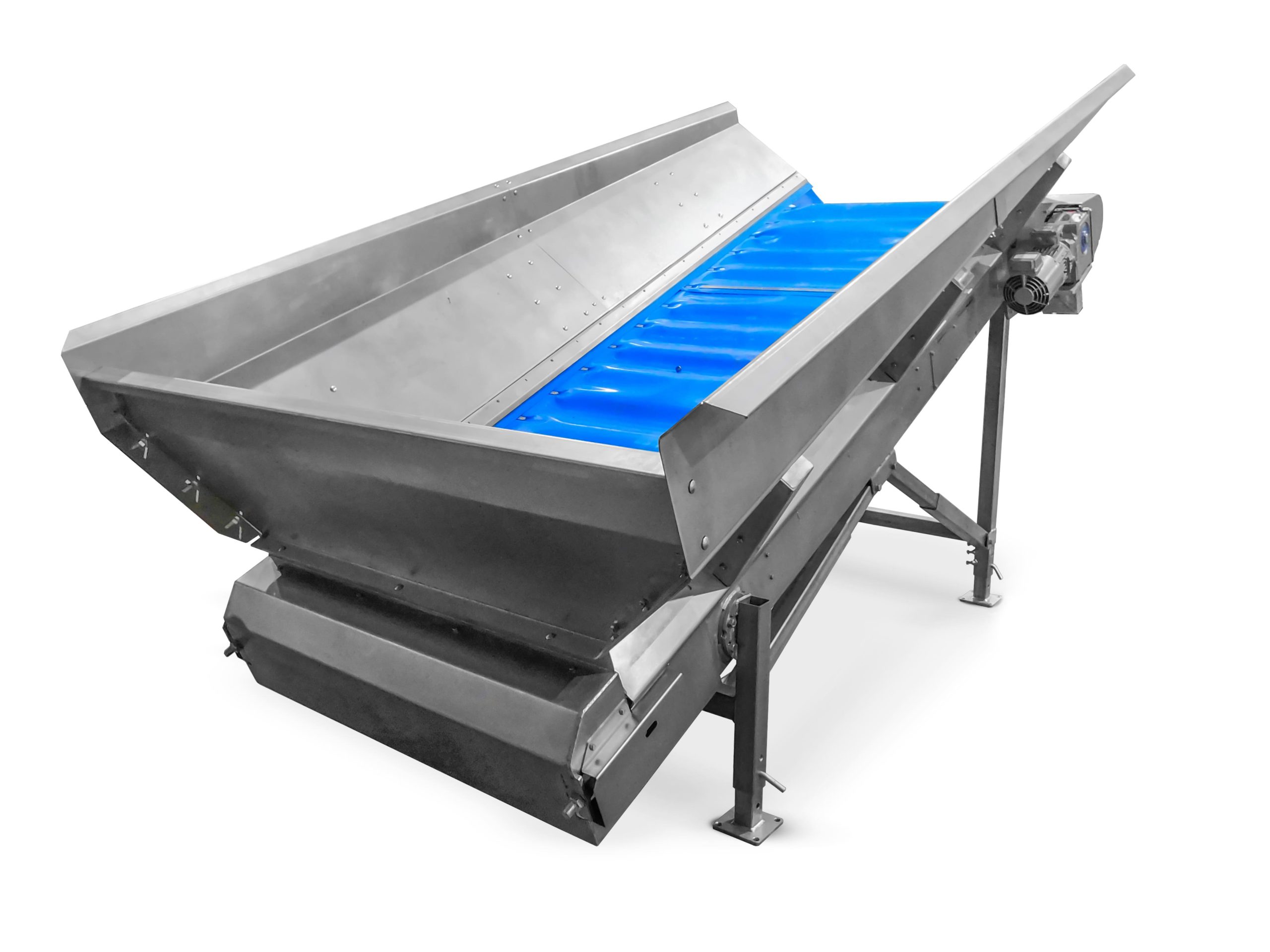

The hopper is designed to feed processing or packing lines and can act as a buffer. The hopper can be fed with produce via boxes and big bags. After the machine is filled, a moving floor conveys the produce diagonally up towards the outfeed. The angle of the floor ensures an even product flow. Additionally, a frequency inverter is installed on the machine to allow for adjustable product flow.

This hopper is mainly used in combination with a box tipper to feed processing or packing lines. The angle of the hopper can be adjusted according to different products to provide optimal flow.

On demand, a sensor can be installed to detect and control the produce output. This sensor sends a signal to start or stop the moving floor, thereby controlling the output of the hopper.

Characteristics

- Models are available in different widths and lengths

- The angle of the machine can be adjusted

- Simple access allows for easy cleaning and maintenance

- Used to feed packing or processing lines

- Simple, durable tensioning system

- A frequency inverter can adjust the floor speed to manage the product flow

- On demand, wheels can be provided for easy relocation of the machine

- On demand, a sensor can be provided to detect and control the output of produce

Specifications

| Width of the belt (cm) | Length of the belt (cm) | Total content (m3) | Effective content (75% filled)(m3) | |

|---|---|---|---|---|

| B 100 | 100 | 250 | 1.6 | 1.2 |

| 100 | 300 | 2 | 1.5 | |

| 100 | 400 | 2.6 | 1.9 | |

| B 120 | 120 | 250 | 2.0 | 1.5 |

| 120 | 350 | 2.9 | 2.1 | |

| 120 | 450 | 3.8 | 2.8 | |

| 120 | 600 | 5.1 | 3.8 | |

| B 160 | 160 | 500 | 5.3 | 3.9 |

| 160 | 600 | 7.0 | 5.2 |

Options

- Material and treatment (frame)

- Electrical control

- Material and treatment (electrical panel)

- Dosing Sensor

- Dosing mill

- Wheels

- Outfeed height

- Material and treatment (legs)